In-Lab vs. On-Site Metrology Services

When customers require a high level of precision that cannot be achieved in the field due to temperature variations, vibration, and other environmental factors, our metrology lab provides the appropriate environment. The lab eliminates these undesirable variables in order to offer high precision metrology services.

In-Lab Metrology Services Include but are not limited to:

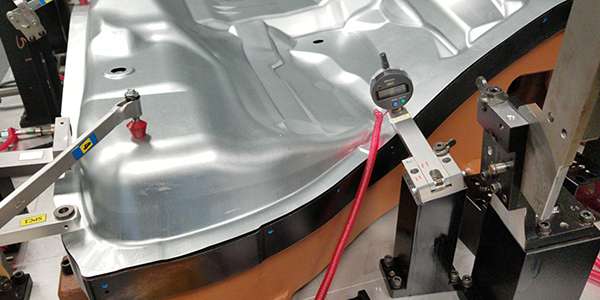

- First article inspections

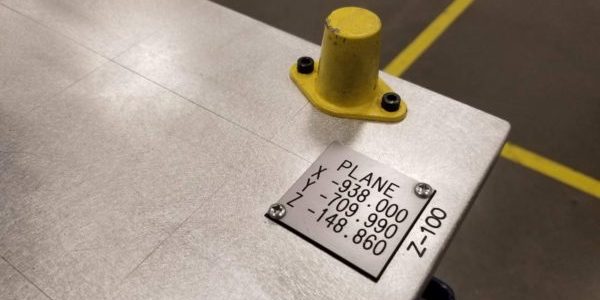

- Fixture Certifications

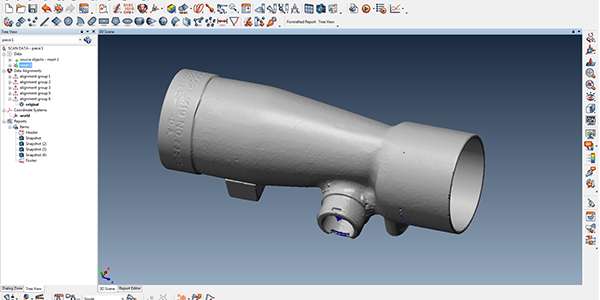

- 3D Scanning Inspections

- In-process inspections

- Statistical Analysis (CPK, PPK, ETC.)

- Root Cause Analysis

- Multi-Piece Inspections

Key Lab Features & Certifications Include:

- ISO-17025 Lab accreditation

- ISO-9001:2008 Document control

- 68 degrees ± 1 degree

- 40% Humidity ± 10%

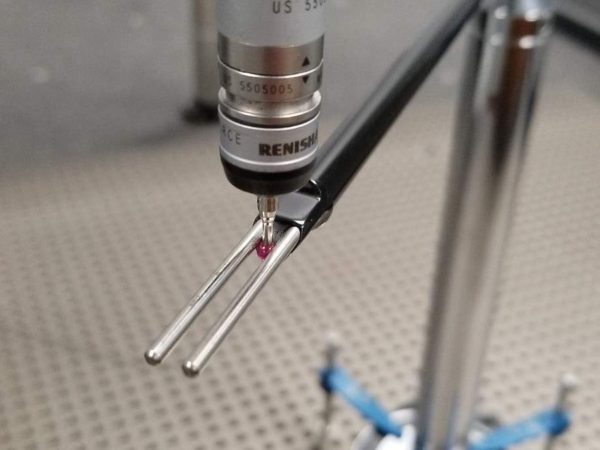

Dimensional Inspection Equipment & Accuracy:

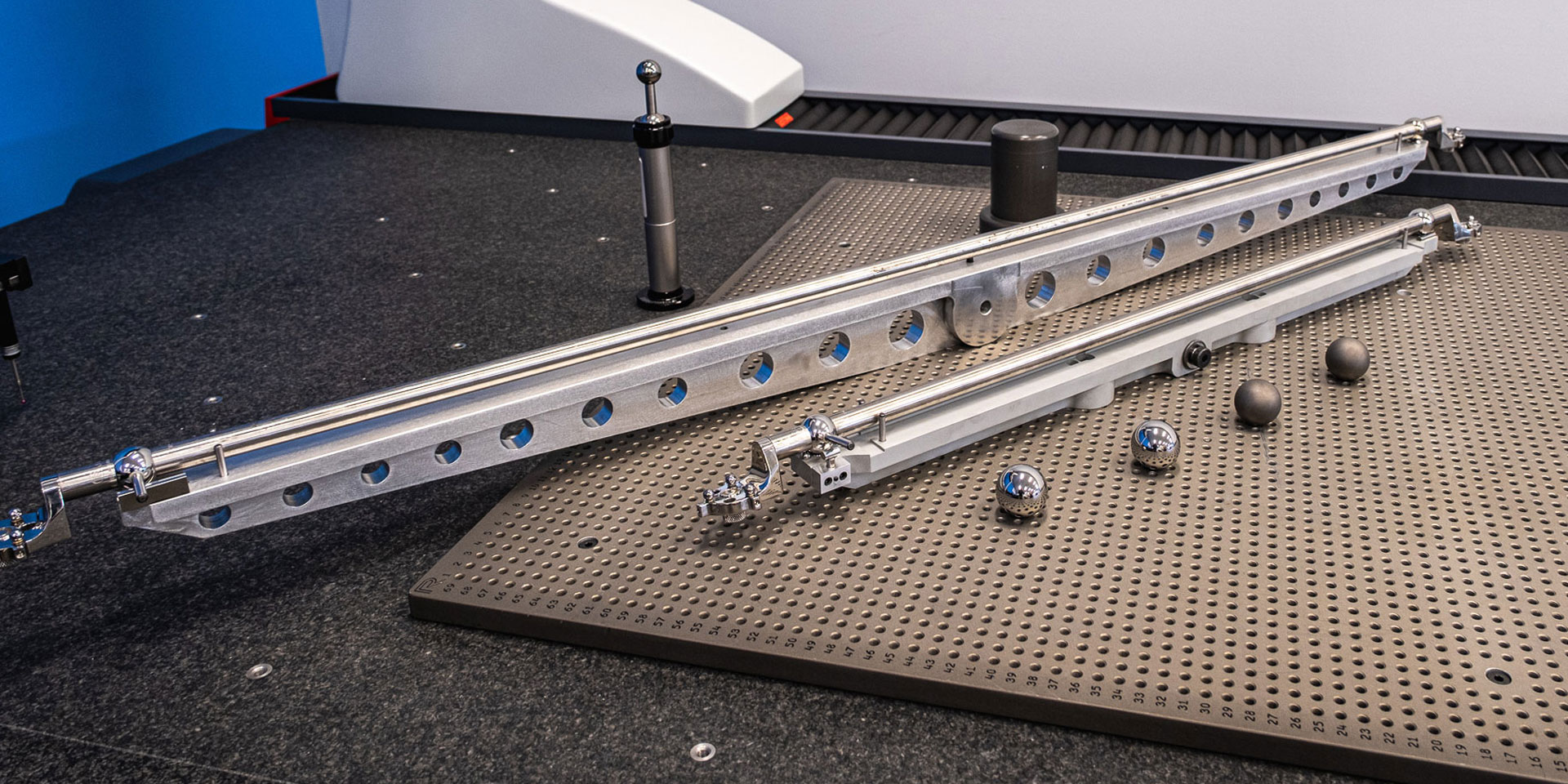

With our fixed bridge DCC CMM, Faro Laser Tracker, and Faro Edge and Quantum Arms we can offer quick turnaround times and precise inspections, certifications and repairs for our customers.

We hold a volumetric accuracy of around six microns using our fixed bridge CMM which allows us to inspect a variety of high precision parts and fixtures to ensure their quality and accuracy. Coupled with our ISO -17025 and ISO 9001 certificates, we can provide a broad range of dimensional inspection services in our lab to meet your needs.

Short Lead Times

We know time is of the essence and pride ourselves in completing 90% of in-lab projects within three days or less. Need a dimensional inspection project sooner or have an object which can’t easily be moved? Check out our portable metrology services or give us a call today.